In industries such as oil and gas, chemical manufacturing, pharmaceuticals, and mining, hazardous environments are a daily reality. These settings often involve flammable gases, vapors, dust, or fibers that can ignite, causing catastrophic explosions. To mitigate such risks, the use of explosion-proof equipment is essential.

However, not all explosion-proof equipment is created equal. Each piece of equipment is classified based on the specific hazards it is designed to withstand. Understanding explosion-proof classifications is critical for selecting the right equipment to ensure safety, compliance, and operational efficiency.

1. What Does ‘Explosion Proof’ Mean?

The term ‘explosion-proof’ refers to equipment designed to prevent an internal ignition from spreading to the surrounding atmosphere, where it could ignite flammable substances. Contrary to popular belief, explosion-proof does not mean that the device is immune to explosions; instead, it ensures that any explosion inside the device is contained.

Explosion-proof equipment is typically housed in a robust enclosure that can withstand internal explosions and prevent sparks, heat, or flames from escaping.

2. Key Standards Governing Explosion-Proof Classifications

Several international standards and regulatory bodies define and govern explosion-proof classifications. Some of the most recognized include:

- National Electrical Code (NEC): Used primarily in North America, NEC defines hazardous location classifications.

- IECEx: A globally recognized certification for explosion-proof equipment.

- ATEX: A European Union directive for equipment used in explosive atmospheres.

- CENELEC: Defines standards for equipment in explosive atmospheres within Europe.

3. Explosion Proof Classifications Explained

a. NEC Classification (North America)

The NEC system divides hazardous locations into three key categories:

- Class: Identifies the type of hazardous material.

– Class I: Flammable gases or vapors (e.g., propane, methane, hydrogen).

– Class II: Combustible dust (e.g., grain dust, coal dust, metal dust).

– Class III: Ignitable fibers and flyings (e.g., textiles, wood fibers). - Division: Describes the likelihood of the hazard being present.

– Division 1: Hazardous material is present under normal operating conditions.

– Division 2: Hazardous material is present only under abnormal conditions. - Group: Specifies the type of material within each class.

– Class I Groups: A (acetylene), B (hydrogen), C (ethyl ether), D (propane).

– Class II Groups: E (metal dust), F (coal dust), G (grain dust).

b. IECEx and ATEX Classification (Global and Europe)

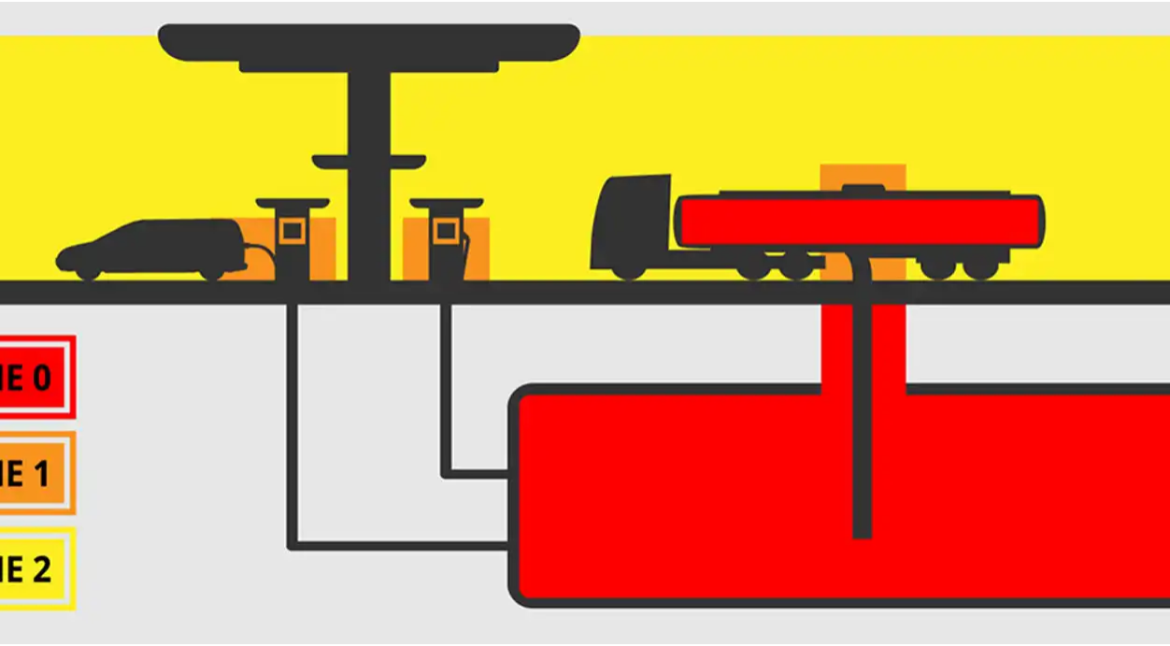

The IECEx and ATEX systems categorize hazardous environments based on zones instead of classes and divisions:

- Zone 0: Explosive atmosphere is present continuously or for long periods.

- Zone 1: Explosive atmosphere is likely to occur in normal operation.

- Zone 2: Explosive atmosphere is unlikely to occur and, if it does, will exist only for a short period.

These zones are further divided into equipment groups:

• Group I: Equipment for use in underground mines.

• Group II: Equipment for use in surface industries.

– IIA: Propane

– IIB: Ethylene

– IIC: Hydrogen or acetylene (most hazardous group)

4. How to Select Explosion-Proof Equipment

Choosing the right explosion-proof equipment involves a thorough understanding of the environment and the associated risks. Here’s how to approach the selection process:

- Identify the Hazardous Area Classification: Determine if the area falls under Class I, II, or III (NEC) or Zone 0, 1, or 2 (IECEx/ATEX).

- Understand the Material Characteristics: Identify the type of gas, vapor, or dust present and its group classification.

- Consider Temperature Ratings: Ensure the equipment’s surface temperature will not ignite the surrounding atmosphere. Explosion-proof equipment is rated by a “T-code” that indicates the maximum surface temperature.

- Verify Certification: Ensure the equipment is certified by a recognized authority (e.g., UL, IECEx, ATEX).

5. Common Applications of Explosion-Proof Equipment

Explosion-proof equipment is used across various industries, including:

- Oil and Gas: For pumps, motors, lighting, and control panels.

- Chemical Processing: For handling volatile chemicals and preventing ignition.

- Pharmaceuticals: In cleanrooms and areas handling flammable solvents.

- Mining: For equipment used in underground operations with explosive gases.

- Food Processing: In areas where combustible dust is present, such as grain mills and sugar refineries.

6. Benefits of Using Explosion-Proof Equipment

- Enhanced Safety: Protects personnel and assets by reducing the risk of explosions.

- Regulatory Compliance: Ensures adherence to safety regulations and standards.

- Operational Continuity: Minimizes downtime caused by accidents or equipment failures.

- Long-Term Cost Savings: Prevents costly incidents and reduces insurance premiums.

Explosion proof classification is a critical aspect of safety in hazardous environments. Understanding the classifications and selecting the right equipment ensures not only compliance but also the safety and well-being of employees and assets.

By investing in properly certified explosion-proof equipment, businesses can operate confidently in high-risk areas, knowing they have taken essential steps to mitigate the dangers of explosive atmospheres.